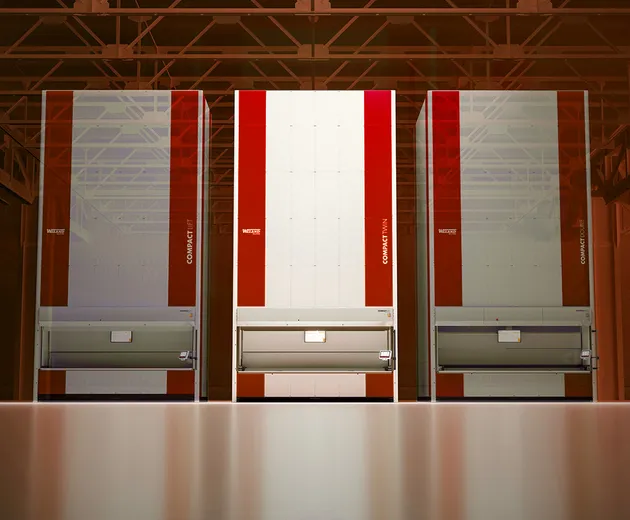

Racks

Vertical storage lifts (also referred to as towers or elevator storage systems) store goods at great heights safely and completely under control. This technology ensures optimum use of space, saving 70% to 90% of the area compared to standard shelving or pallet racking and significantly speeding up material flow. Our tower storage systems, delivered turnkey to customer needs, deliver a visible effect immediately after commissioning in the warehouse. The automatic lift system is simple, convenient to operate and requires no time-consuming maintenance. It allows you to reduce labour costs, keep an efficient overview of items in stock, while taking up much less floor space than traditional solutions. When properly integrated, vertical storage lifts can significantly speed up material flow, making them an ideal modular solution for e-commerce, for example. The return on investment for VertiFlex towers is faster than one would expect. Most projects expect a payback period of 12 to 24 months.

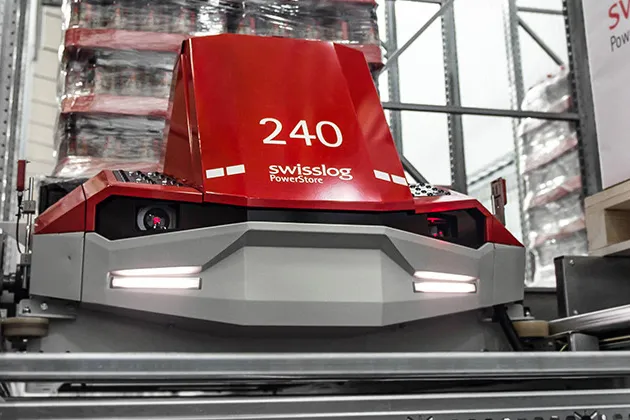

Robots

Our Geek+ robot solution is a cutting-edge technology platform focused on intelligent robotic solutions that transform warehouse operations. This advanced technology uses state-of-the-art robots designed for a variety of activities including picking, sorting, transporting and storing goods.

Cranes

Fully automated systems increase the quality, flexibility and efficiency of the warehouse. We offer a wide range of technologies for automated storage and picking of pallets and smaller goods such as cartons or crates.

VertiNode®

Software for automated logistics with the latest artificial intelligence technology and compatible with most storage systems. VertiNode® has many uses, but excels especially in the e-commerce environment. The comprehensive solution allows the integration of AI outputs directly into the company's processes. The ERP system can learn from VertiNode® immediately after the order is handed over for picking to the target picking position and the expected processing time, this information can be used for instant communication with the client in the order processing process. Order statuses are accessible via the API interface. The ERP system (and consequently the client) can find out at any time when the shipment will be dispatched, that the shipment has started and successfully completed or delayed, the tracking ID of the order for immediate confirmation by the carrier, all to increase transparency and delivery speed.