Need to store a Bugatti Chiron or Honda Repsol?

We supplied Astra with four Compact Twin vertical storage lifts, which are controlled by our own VertiNode® warehouse control system.

Company ASTRA has been operating on the market for more than 30 years as a leading distributor of modeling supplies, toys, tools, and equipment for hobby and professional modeling use. The company's portfolio includes thousands of items from global brands, which are distributed through its e-shop and an extensive network of business partners. The constant growth of the product range and increasing customer demands place high demands on warehouse logistics and order picking speed.

Initial situation and customer needs

Astra Model planned to optimize its storage space and implement an automated system with advanced control to ensure efficient use of space and increase the efficiency of goods handling with greater accuracy and lower error rates. The company was looking for an automated storage solution that would enable it to:

- make maximum use of the available height of the warehouse,

- speed up and improve the accuracy of the picking process,

- simplify inventory management,

- prepare the infrastructure for connection to the higher-level information system.

Delivered solution

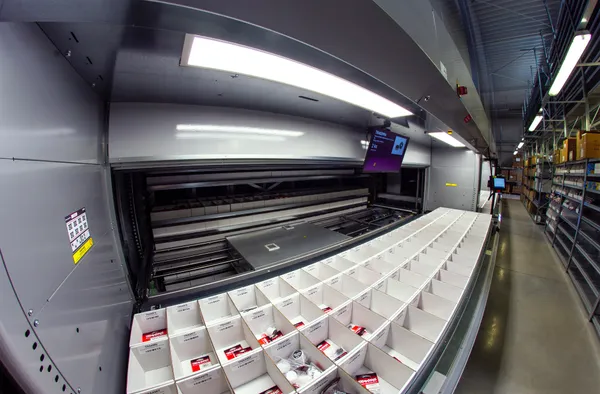

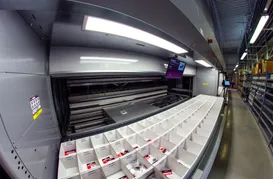

The optimal solution to meet the requirements for an automated solution was four Compact Twin vertical stackers, which were delivered in two phases. These are 3660x820x6476 tower models with a shelf load capacity of 300 kg. The delivered solution provides a storage capacity of 27 m3 per tower, i.e. more than 100 m3 of compact and secure storage.

Compact Twin lift systems are equipped with a double extractor, which allows parallel preparation of shelves while goods are being handled (stored or picked) from the previous shelf, which is in the handling opening. The shelves, 3,660 mm wide and 820 mm deep, are optimized for storing small to medium-sized goods, which is ideal for storing Astra's range of modeling and hobby products.

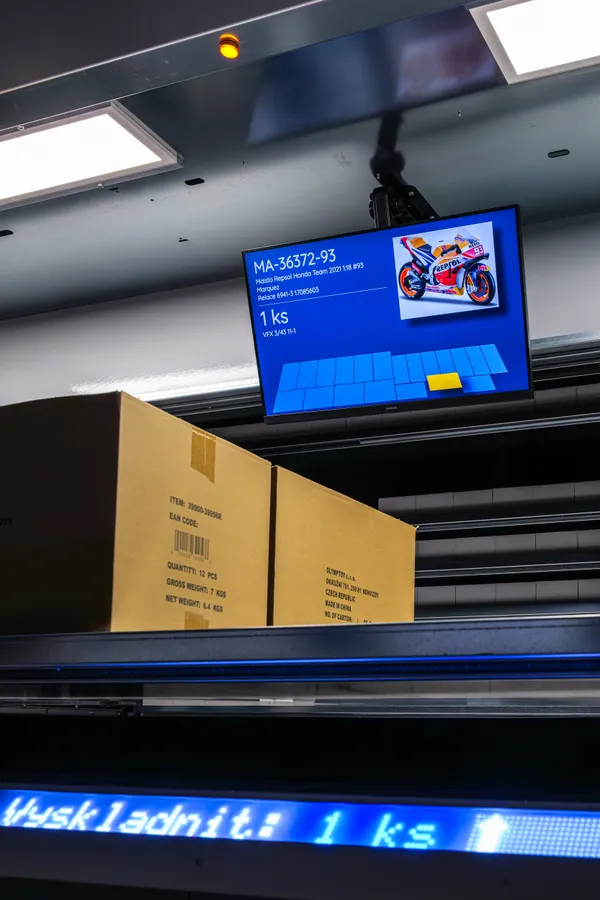

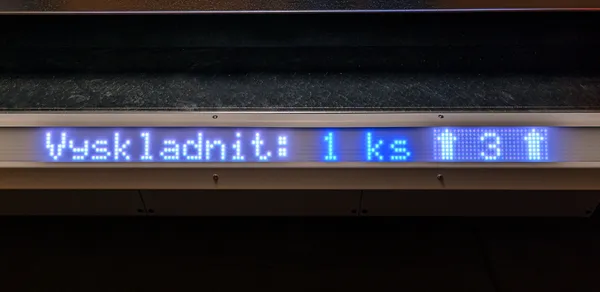

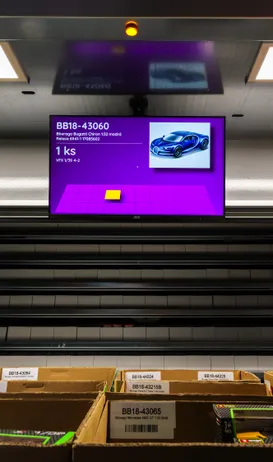

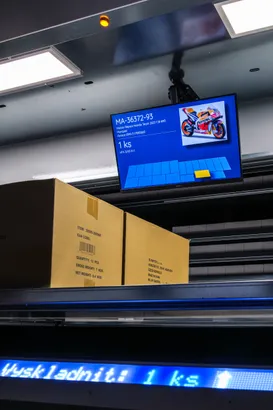

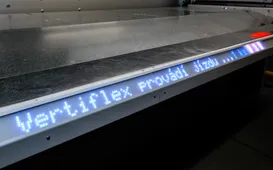

The machines are equipped with a wide range of accessories that increase operational efficiency, reduce picking errors, and create a safer working environment for operating personnel. For faster and error-free picking, the stackers are equipped with a full-color LED guidance bar, which is manufactured by our company. The towers also have picking displays that clearly inform the operator about the goods being picked, including a description, image, item number, number of items being picked, and the position of the goods on the shelf. The vertical stackers are also equipped with safety sensors and sound insulation for a comfortable and safe working environment in the warehouse.

The project also included the implementation of the VertiNode® control system (www.vertinode.ai), which provides:

- management of warehouse items and their movement,

- control of stocking and destocking with FIFO and batch support,

- integration with the information system via REST API,

- performance reporting and online monitoring,

- use of tools for optimizing item placement, picking planning, and order fulfillment time prediction.

All these WCS VertiNode® functionalities lead to higher warehouse performance, faster order processing, and lower error rates when handling goods.

The delivery also included the dismantling of the original racks, modification of the electrical installation, installation of protective elements, and complete training of the operators. The project also includes a service contract with the Silver Fix package, which provides comprehensive services in a scope that is optimal for the smooth operation of elevator systems, taking into account the expected operating time and load on the machines.

Benefits of the solution

The implementation of the VertiFlex vertical lift system has brought ASTRA significant improvements in key areas:

- Space efficiency – utilizing the height of the hall has freed up more than 60% of the original storage space.

- Speed and accuracy of picking – thanks to the Compact Twin system with pick-to-light support and VertiNode® algorithms, shipping times have been significantly reduced.

- Ergonomics and safety – operators always work at an optimal height without the need for handling at heights, and access to materials is restricted to authorized personnel.

- Full digitization and control – online monitoring, reporting, and ERP integration have ensured a transparent flow of information and eliminated errors.

- Scalability for the future – thanks to the modularity of Compact Twin lift storage systems, warehouse capacity can be easily expanded in the future to support Astra's business growth.

Conclusion

The project for ASTRA company is a modern example of how powerful Compact Twin storage technology can be combined with VertiNode® control software. Thanks to the partnership with VertiFlex the customer has gained a solution that combines high storage capacity, speed, and accuracy with smart control and readiness for future integration. This project confirms that the digitization and automation of warehouse processes are key elements for the competitiveness and long-term sustainability of e-commerce and retail companies.