Bidfood Czech Republic: Smart storage for the future of food logistics

Don't be limited by the height of your warehouse! We installed two Comtact Twin vertical lift systems outside the warehouse premises for Bidfood. This makes it possible to have storage lifts that are taller than the original warehouse premises.

Bidfood Czech Republic is a leading food supplier for gastronomy and retail. Its warehouses and distribution centers supply thousands of restaurants, schools, hotels, and shops across the country every day. With the vast number of items and high turnover, it is crucial for Bidfood to ensure that storage and order fulfillment processes are fast, reliable, and safe.

The challenge

The warehouse in Kralupy nad Vltavou was modernized by installing two vertical lift systems, which increased efficiency in goods handling. Due to limited ceiling height, the towers could not be installed directly inside the warehouse. Instead, they were placed in an enclosed external casing, with the access opening connected to the warehouse interior.

The goal was to save space, speed up order picking, and unify warehouse processes with other depots. Traditional shelving no longer met the requirements, especially with the increasing order volume and demand for accuracy. An interesting feature of this installation is the fire shutter between the vertical lifts and the warehouse, which in case of emergency separates the technology from the rest of the facility, preventing fire from spreading and damaging the machines.

The solution by VertiFlex

Bidfood selected VertiFlex’s solution:

- installation of two Compact Twin vertical lifts nearly 8 meters high,

- each machine offers over 35 m³ of capacity with more than 40 trays,

- trays with a load capacity of 300 kg are handled by a dual extractor, preparing the next tray while the operator is still working on the previous one,

- safety sensors, light barriers, and ergonomically placed access openings ensure both safety and comfort even during heavy workloads.

The Compact Twin also uses space down to the last centimeter – trays can be placed very close to the floor, providing more storage area than conventional solutions.

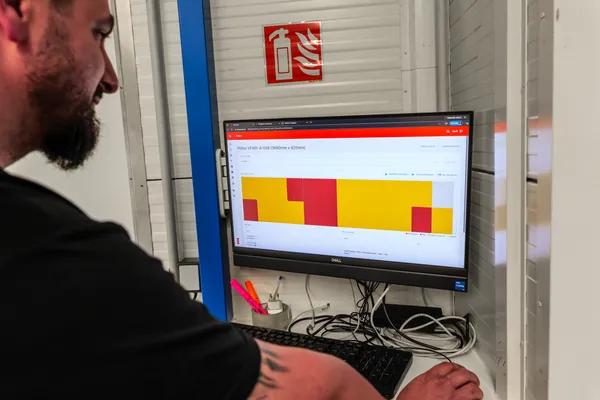

Digital control with VertiNode®

The hardware was complemented by the VertiNode® control system, implemented to the same standard already used by Bidfood in other warehouses. This enabled seamless integration with the company’s database and standardized processes.

VertiNode® provides clear item management, inbound and outbound control, batch and FIFO handling, as well as modern tools for monitoring the entire operation. Thanks to its modular design, Bidfood can easily expand with new user accounts, access openings, or advanced features without complex modifications.

Benefits for Bidfood

By implementing Compact Twin lifts and VertiNode®, Bidfood has gained:

- significantly more storage capacity without expanding floor space,

- faster order picking and shorter lead times,

- safer and more ergonomic working conditions,

- integration with other warehouses and a unified inventory management system.

Partnership for long-term growth

The Kralupy project exceeded expectations and led to the extension of cooperation on equipping further warehouses in the Czech Republic with vertical automation technology. This collaboration demonstrates that modern automation is not just about machines, but about connecting technology, people, and processes. With this solution, Bidfood is ready to respond flexibly to growing customer demands and strengthen its position as a leader in food distribution.

Are you planning to take your warehouse to the next level? Contact us – we will design a solution tailored to your business.