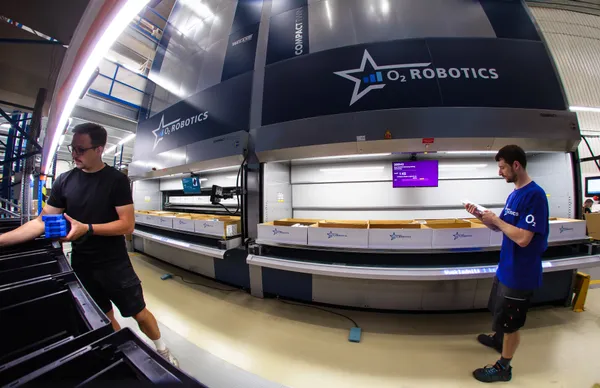

Modern warehouse automation for O2 Czech Republic

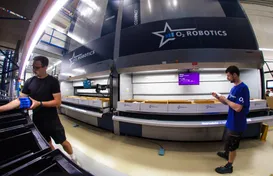

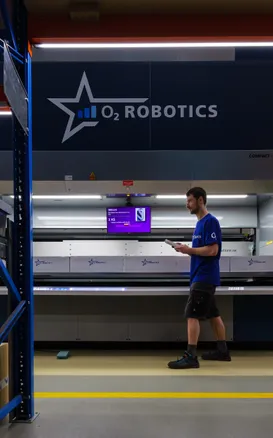

The automation of logistics processes at the O2 Czech Republic warehouse has increased storage capacity thanks to the installation of two Compact Twin vertical storage lifts. Warehouse operations are controlled by our VertiNode® warehouse control system.

O2 Czech Republic a.s. is one of the largest telecommunications service providers in the Czech Republic. The company connects millions of customers not only in the area of mobile and fixed services, but also through extensive ICT projects. In order to maintain a high level of customer service and respond flexibly to market needs, it is essential to have logistics and warehouse inventory management under absolute control. This was precisely why O2 decided to invest in a modern warehouse solution.

The challenge: more space, faster shipping, fewer errors

Traditional storage in traditional racking systems was no longer sufficient at the O2 warehouse. The company needed to use the available space more efficiently, speed up the picking process and, at the same time, improve the clarity and control of its inventory. Another key requirement was full integration with the SAP enterprise system in order to combine physical logistics with digital process management.

Compact Twin and WCS VertiNode® as the optimal solution

The designed and delivered solution, in cooperation with BITO Skladovací technika, is based on a combination of state-of-the-art hardware and intelligent control software.

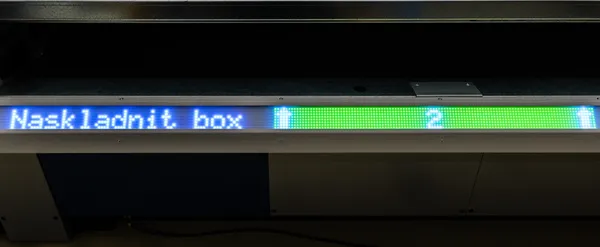

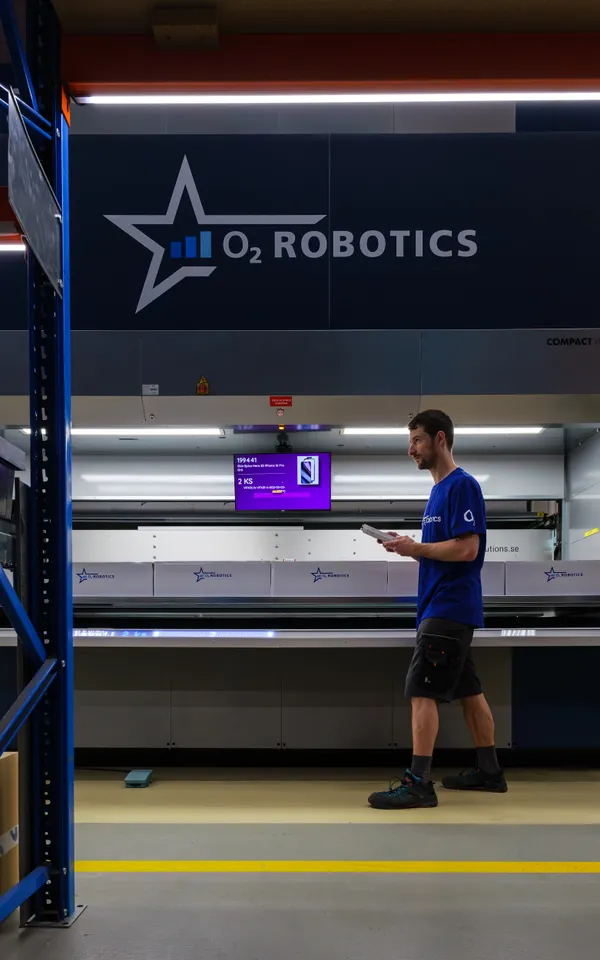

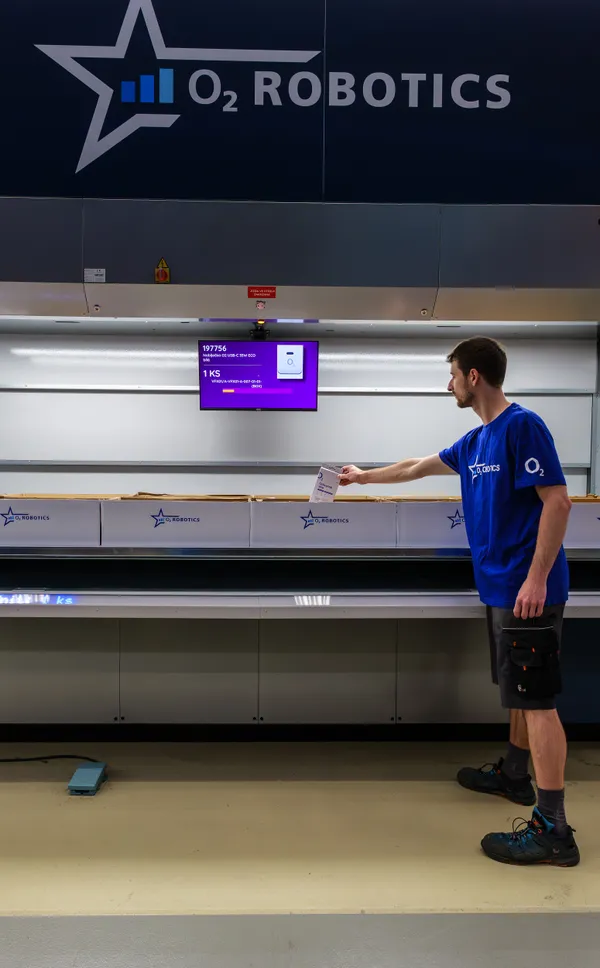

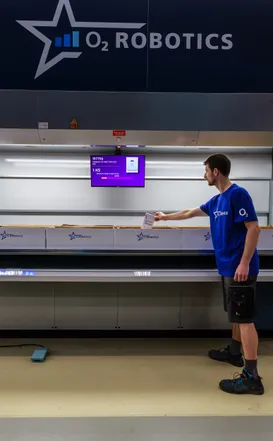

The basis is two Compact Twin vertical storage lifts with a height of almost ten metres. Thanks to the double lift with Twin technology, it is possible to prepare the next shelf while the operator is handling the goods on the currently extended shelf. This dramatically increases picking performance and minimises operator downtime. Each unit can hold 48 shelves with a load capacity of 300 kg and dimensions of 3,660 x 820 mm, which means tens of cubic metres of storage capacity in a relatively small area. This allows the customer to make full use of the height of the hall and free up floor space for other processes. The vertical lifts are connected to pick-to-light picking into gravity racks, further increasing efficiency and eliminating errors in order picking.

- 2 Compact Twin units with a height of 9,476 mm, shelf width of 3,660 mm and depth of 820 mm.

- Load capacity of one shelf: 300 kg, number of shelves: 48.

- Total capacity of one device: 43.14 m³ with an area of 144 m².

- Automatic measurement of material height in 25 mm increments and intelligent shelf placement for maximum space utilisation.

- The double lift allows another shelf to be prepared while the operator is working, which significantly speeds up picking.

- Built-in safety features: overhang sensors, light barrier, emergency operation option.

- Web interface and remote diagnostics option ensure easy monitoring and servicing.

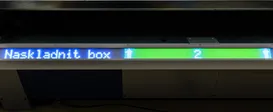

An equally important part of the project is the implementation of the VertiNode® control system. This software brings digital intelligence to the warehouse – it manages items, optimises their placement, communicates bidirectionally with SAP and uses artificial intelligence to evaluate the fastest picking process. The system can predict order fulfilment times, recommend warehouse reorganisation based on real data, and also ensures intuitive operation for staff using a pick-to-light system.

Safety, service and reliability

The delivery also includes advanced safety features that protect both staff and stored materials. Sensors, light barriers and emergency mode ensure maximum safety during daily operation. The GOLD FIX service package supports the smooth operation of lift systems and includes preventive inspections, remote diagnostics and the ability for technicians to respond immediately without the need for physical intervention. This significantly reduces costs and increases system availability.

Acceleration, efficiency and control are the result

The implementation has brought clear results for O2. There has been a significant increase in storage capacity with maximum utilisation of warehouse height. Order dispatch has been accelerated thanks to Twin extractor and WCS VertiNode® technology. Operators work ergonomically and without unnecessary movements, and picking errors have been minimised. Integration with SAP allows company management to monitor current stock levels in real time and plan logistics with maximum accuracy.

- Efficient use of space – stackers utilise the full height of the hall, increasing capacity by tens of per cent without expanding the floor space.

- Faster picking – Twin extractor and VertiNode® planning minimise downtime and reduce dispatch time.

- Integration with SAP – full digitisation of processes allows O2 to check inventory online and optimise goods flows.

- Safety and ergonomics – goods are only accessible to authorised personnel, and operators always work in the optimal position.

- Predictive management – thanks to VertiNode®, O2 has access to order processing time predictions and recommendations for warehouse reorganisation.

The project clearly demonstrates that the combination of modern Compact Twin automated hardware and VertiNode® control software not only provides an immediate increase in efficiency, but also long-term flexibility. O2 has thus gained a strategic tool that will support further growth and digitisation of logistics processes. Would you also like to transform your warehouse into an intelligent logistics centre? Contact us – we will be happy to design a tailor-made solution for you.