Shelf-to-Person robotic warehouse for a leading distributor of electrical installation materials

K&V Elektro is one of the leading distributors of electrical installation materials in the Czech Republic. With a constantly expanding product range, a modern approach to logistics and an emphasis on operational efficiency and customer satisfaction, K&V Elektro decided to fundamentally modernise its distribution infrastructure at its new distribution centre in Nehvizdy.

Project objectives

The project had several key objectives defined at the outset, ranging from increasing capacity to improving accuracy and, of course, operational efficiency, taking into account the long-term shortage of human resources on the labour market. Specifically defined project objectives:

Increase warehouse capacity to store more than 14,000 SKUs

Speed up the order picking process (up to 7,700 lines/day)

Automate goods handling operations

Increase picking accuracy and operational safety

Optimise the use of storage space

Integrate with the company's existing SAP ERP system

Robotic warehouse design

The automated robotic picking warehouse system is located on a concrete mezzanine with a load capacity of 1,000 kg/m2 and operates in two shifts on working days.

The Shelf-to-Person picking technology used consists of:

Racking system

25x Geek+ mobile robots

2x inbound workstations (receiving)

3x outbound workstations

IT system including

interface between WCS (warehouse control system) and K&V Elektro's enterprise information systém

RMS system for robot control

reporting tool

Racking system

The shelving racks for robotic solutions are 2.8 m high. They are equipped with 6 shelves for storing goods, and each rack has a maximum load capacity of 1,000 kg. There is space for transport robots to pass under the first shelf.

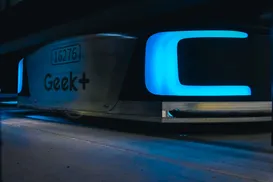

Geek+ robots

The warehouse is equipped with 25 Geek+ P800 transport AMR robots, which are used to transport individual racks to the inbound station, store the racks and transport them to the outbound station. The robots are navigated using QR codes on the floor.

Inbound workstation

Goods are received via two inbound workstations for placing goods on racks. Once the quantity of goods has been confirmed as having been placed on a specific rack, it is transported by a transport robot to a free location in the storage area. The receiving capacity is up to 153 items per hour.

The design of the goods receiving workstation allows this workstation to also be used for picking goods during seasonal peaks. This makes it possible to respond quickly to an increased number of orders and process them within standard times thanks to the increased number of picking workstations.

Outbound workstation

Goods are picked according to orders at outbound stations into KLT containers, which are located in Put-to-Wall racks equipped with Pick-to-Light technology. The picking workstation is equipped with a panel displaying information about the goods being picked, the quantity and their location in the rack. Operators also have an optical pointer at their disposal for faster guidance. The combination of all guidance tools eliminates errors in picking goods and completing orders. Operator performance is calculated at 10-15 seconds for picking the required quantity of a specific item.

The daily picking performance is 6,020 order lines per day, with a capacity of up to 7,700 lines per day during seasonal peaks. The hourly performance of the system is up to 550 lines per hour.

Software and system integration

As part of the implemented solution, a WCS control system with Czech localisation was implemented to ensure the coordination of robotic operations and smooth integration with the customer's ERP/WMS system (SAP – mibWMS). A key element is the RMS (Robot Management System) module, which ensures route planning, operation control and real-time monitoring of robot status via a WI-FI network. This system supports the Shelf-to-Person picking strategy, where robots automatically bring racks to the picking stations. Here, the control system uses touch screens and optical indicators to display accurate information about the quantity and location of the goods being picked to the operator. The pick-to-light system then guides the operator to the target location, where they confirm the operation by pressing a button. The system is closely integrated with SAP BW, enabling automated exchange of data on SKUs, picking and replenishment tasks, results and identified discrepancies. The delivery also includes the necessary hardware equipment for workstations, including operator stations, readers, optical devices and displays. Support for the necessary software layers for smooth communication between all system components is also provided.

Service support

Service support is also provided for the operation of the robotic warehouse, guaranteeing service intervention within an agreed response time of 12 hours from the reporting of a fault. A dedicated 16/5 service hotline is in operation. The service team carries out regular inspections and training for the customer's operators and maintenance technicians.

Project benefits and further development

The implementation of an automated robotic solution brings a number of significant benefits to K&V Elektro, which are positively reflected in the efficiency and quality of warehouse operations. There has been a significant increase in warehouse throughput and a simultaneous reduction in errors during goods storage and picking. Process automation saves labour, speeds up goods handling and optimises overall operations. The solution is designed with an emphasis on flexibility – the system easily supports a two-shift operation and is able to adapt to fluctuations in operations, such as during seasonal peaks. The connection to reporting tools in the SAP BW environment ensures a high level of transparency over warehouse data and enables accurate monitoring of performance and deviations. Last but not least, the system contributes to greater operational safety and makes efficient use of available warehouse space, thus fulfilling K&V Elektro's strategy of modernising its logistics processes.

The next phase of the project will see the implementation of WCS VertiNode®, which will further optimise operations and increase the performance of the entire warehouse. VertiNode® is a special control and integration platform for automated logistics. It is compatible with most warehouse systems and was developed by VertiFlex's internal software team. You can read about the features offered by VertiNode® at www.vertinode.ai.